Why is my concrete tank leaking?

Linear horizontal cracks following internal reinforcing.

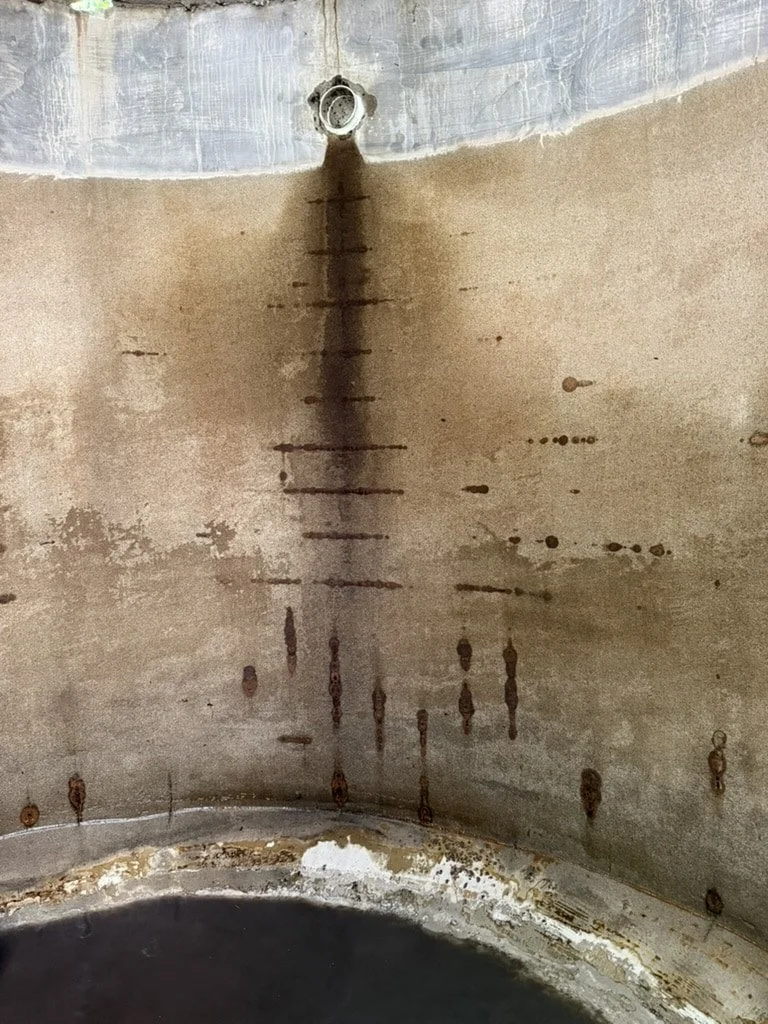

Internal surface of a concrete tank showing rust spots following internal reinforcing along with a visible high water line where the plaster lining above the water is still in good condition.

Most of the leaking concrete rainwater storage tanks the we install Tankliners to have all failed for the same reason.

Rainwater being collecting in the tank will come in with a pH somewhere between 6.5 & 7.5.

As this fresh water sits in the tank it will be in constant contact with the internal surface of the tank, usually a plaster render or bare concrete.

This plaster or concrete contains cement as a binder, Portland cement, when hydrated during manufacturing of the tank, the cement forms portlandite (calcium hydroxide crystals) which can be leached out of the cement mortar lining by water low in calcium content (rain water).

Over time more of these lime compounds are leached out of the tank walls removing layer after layer of material with the sand aggregate falling away, eventually exposing the reinforcing steel set within.

Once this steel sits wet it will oxidise in place. This is often observed in the tanks we work on with very obvious rust stains around the internal surface of the tank.

This oxidation of the steel will see rust jacking (oxide jacking) take place where the steel oxides can expand up to 10x the original volume of the steel.

This rust jacking leads to cracks or holes in the sidewall of a concrete tank - often quite linear following horizontal & vertical reinforcing - see image inset.

Anyone who has ever worked on rust on their vehicle will tell you unless you can cut out all of that rust before repairing and sealing the rust will come back.

In a tank removing the rust is not possible, there’s no feasible method of getting to that oxidised steel without cutting the tank to pieces.

A plaster layer applied over rust may hold in the short term but will eventually suffer the same fate as the tank with the surface that plaster is applied to being gradually pried apart by oxide jacking and the plaster layer having no ability to stretch across that widening crack.

This is where Geomembrane Tankliners come in - they really are the only way you can remedy this issue when measuring by years or decades.

Geomembrane Tankliners are loosely fixed to the tank at the top of the sidewall only and not adhered to the internal surface of the tank in any way, relying on the water it contains hold it flush against the sidewall and floor.

This allows the Tankliner to bridge over any cracks and voids without being reliant on those cracks staying exactly where they are.

The Permaflex fPE500 Polyethylene Geomembrane Membrane Dynamics use for Tankliners is rated to 1000% elongation at break point - in english thats a 10x stretch before tearing meaning that 1mm crack needs to become a 10mm crack to be of concern.

Secondary to the Tankliners ability to bridge cracks and gaps is the fact that an installed Tankliner removes fresh water from contact with the concrete surface, halting degradation of the tank & extending the lifespan of the entire system.

Diagram showing mechanism for leaching of Calcium Hydroxide from cement based tank sidewall.

Source: CEED Seminar Proceedings (2016) Investigation of the Effect of Water Quality and Lime Dosing on Mild Steel Cement Lined Pipes, J. Le, J. Leggoe, G. Ash & T. Christen. https://ceed.wa.edu.au/wp-content/uploads/2017/02/9.-Le-Water-Corporation-Water-Quality-Lime-MSCL-Pipes.pdf